News & Events

Live Cattle IMF Measurements - An update

1 May 2024

We’re doing it – measuring intramuscular fat of live cattle!

This is an exciting new application of Marbl™, but not too far from our hot carcass IMF grading and beef work. The photo shows our prototype Marbl™ Live sensor in use, making our MRI-like measurement. We directly measure the intramuscular fat; no image analysis is needed.

Going forward we will continue measuring more cattle and referencing against gold standard laboratory %IMF measurements. Our goal is to achieve objective IMF measurement for producer decision making.

Thanks to Meat & Livestock Australia and University of New England for their support. Follow us to track our progress.

Prototype Marbl Live™ sensor in use, measuring cattle IMF

Automated IMF at 8-12 carcases per minute - our next step

26 March 2024

We are pleased to announce we’re underway with realising hot, automated IMF measurement for higher throughput lamb-processors. Our concept includes twin-Marbl™ sensors and pairs of carcasses being measured at the same time to accommodate chain speeds of 8-12 carcasses/minute.

AMPC & MLA are supporting a project to demonstrate this system, in use, on the main chain, in a processing facility in Australia.

If you’re a processor targeting MSA eating quality pathways and are keen to be involved, then please contact AMPC with an expression of interest.

Twin-Marbl™ Sensor Prototype

Hot-lamb %IMF grading: over 100,000 carcasses automatically measured

15 February 2024

Are you a lamb producer/processor who wants to differentiate product but has been constrained by equipment and staff to operate it? Our new automated system may be the solution.

Following our trial-project announcement in March 2023, we’ve proven our system and validated IMF measurements in-line, across two seasons. Over 6 months we’ve measured well over 100,000 carcasses at the end of the slaughter-floor.

Our single sensor system is suited to processors operating at chain speeds of 4-6 carcasses/minute. As the system is fully automated, if staff numbers are down, no compromising on value-adding data.

We’re doing a soft launch of our lamb system and wish to talk with interested processors and producers who want to position their top-end product above the rest.

A system for faster chain speeds and equipment accreditation is a work in progress so follow us for further updates!

Live Cattle IMF Measurements - On it’s way!

7 February 2024

It’s been a mission but we’re excited to soon be trialing our new, prototype gear to measure the IMF of cattle. Here’s a photo of the gear all packed down into the base of our modified crush.

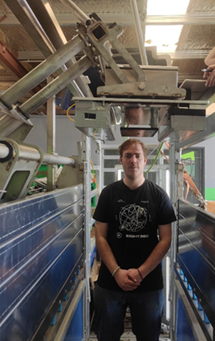

And, before packing down, this is what the system looked like. Here, you can see “Marbl™ Live” in its rest position, fitted to a sensor mount and manipulation assembly. Anthony, our technician, stepped into the photo to provide some context of scale. With our prototype and our in-line lamb work, we’ve shown our Marbl™ sensor can accurately measure %IMF, and we’re looking forward to working with a wider team including Advanced Engineering Solutions and the University of New England to make our MRI-like measurements. Thanks to Meat & Livestock Australia for their support of this project.

Marbl™ Live packed down into the base of a modified crush

Anthony standing within the Marbl™ Live

inMR's sharing with the International Science Community

5 October 2023

Were you aware that our automated, non-invasive intramuscular fat (IMF) lamb grading system is taking magnetic resonance into new territory? We're leveraging its maturity and accuracy as a proven method, it's speed and robustness to tailor it's use in the meat industry.

Over the last month, we've proudly shared our new application of magnetic resonance internationally. Our CTO, Evan McCarney presented our work on the hot lamb grading at the International Conference on Magnetic Resonance Microscopy Materials, Molecular Processes and Engineering in Singapore, and our Technical Director, Robin Dykstra responded to an invitation to publish a peer-reviewed paper titled Automated Eating Quality Measurements on Lamb Carcasses in a Processing Plant Using Unilateral NMR (published in Applied Magnetic Resonance).

In a scientific domain where much is known, it's exciting to be pushing the boundaries and that's the feedback we've received. With time, we'll be taking the technique further, from IMF measurement of carcasses to IMF measurement of live animals and then, to other meat-eating quality traits - there's a lot of additional information in a magnetic resonance signal and we're only getting started.

We've just opened our LinkedIn account, so click below to stay up to date and follow our progress.

Marbl™ for Live Cattle

4 September 2023

inMR is broadening the potential of the Marbl™ non-destructive IMF sensor, from use for hot lamb carcass-grading to live cattle. This work has the support of MLA and was a successful response to a call for tender to develop solutions for objective measurement of live animals.

Six months in, we’re well advanced with the build. We now have a Marbl™ sensor for beef, and this will be integrated into a modified crush. Testing to prove the use on live cattle is planned for November 2023 – February 2024. We’ll be cross-referencing our live measurements with IMF at slaughter across different cattle breeds following 100 days and 300 days on feed.

This project highlights the versatility of our Magnetic Resonance technology. It can be used for lamb and beef, and it can be used for hot or cold non-destructive grading. Lamb carcasses are graded hot at the end of the slaughterfloor in our automated equipment – the ‘hot’ measurement gives processors grading information at the start of manufacturing and opens the door to sorting and manufacturing by grade. Taking the same technology further back in the value chain, onto the farm/feedlot, to inform producer decisions gives a significant point of difference as an IMF measurement technology that can both grade hot carcasses and measure live animals.

inMR is delighted to be able to bring a mature and proven technology to new applications. We do so thanks to our deep understanding of Magnetic Resonance and materials handling equipment.

We’ll be sharing results from our Live Cattle trials next year, but please contact us sooner if you’re interested in learning more.

Ovation NZ partners in ground-breaking research of IMF measurement programme

3 March 2023

Ovation New Zealand Ltd (Ovation) is partnering with inMR Measure Ltd (inMR) to test the development of an Intramuscular Fat (IMF) lamb grading technology, with support and co-funding from the Ministry for Primary Industries’ Sustainable Food and Fibre Futures (SFF Futures) fund.

New sensor tool helps to measure eating quality in sheep meat

21 April 2023

Developed by inMR Measure, the Marbl™ technology tool uses a single-sided nuclear magnetic resonance sensor alongside the longissimus muscle to capture IMF measurements. The sensor tool can be installed into existing carcass handling equipment to measure hot carcasses.

Ovine IMF measurement production prototype

3 March 2023

AMPC worked with inMR Measure to design and build a prototype system for non-invasive, automated, percentage intramuscular fat (IMF) measurement of lamb and to prove application in processing plants.

Prototype Single-sided NMR for non-destructive IMF measurement

29 June 2022

This project developed, tested and delivered positive proof-of-concept that an NMR configuration suitable to use on uncut lamb carcasses has shown potential to provide this measurement.

IMF of primals – end of processing line measurement using NMR - stage 2

29 June 2022

AMPC partnered with inMR Measure to trial a magnetic resonance sensor to conduct intramuscular fat measurements (IMF) of sub-primal cuts in a beef boning room.

Bovine IMF measurement production prototype stage 1

25 June 2021

This project funded the investigation of how Nuclear Magnetic Resonance (NMR) technology can be extended and implemented to measure beef carcasses in a meat processing plant